I’ve spent the last week and a bit helping to fix one of the four capacitor banks in MAGPIE. It’s been a pretty tedious time, taking apart lots of components, and carefully cleaning them before reassembly. The maintenance has, however, given me a good insight into the workings of MAGPIE.

We use a lot of fluids to perform various tasks, from resisting electrical current, to keeping things clean, and these fluids need to be frequently pumped places, replaced, cleaned or stored somewhere, leading to the inside of MAGPIE looking a little bit like a chemical processing plant.

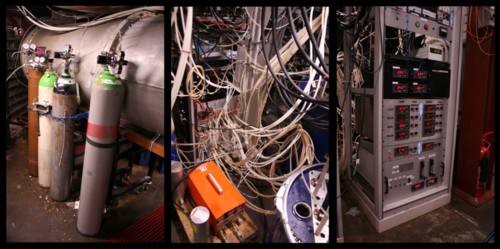

Here’s three pictures from our gas system. We use two main gases – sulphur hexafluoride (SF6) and dry air (which is literally air with the water vapour removed). The former is a heavy gas that smells unpleasantly like rotten eggs, but it’s an excellent insulator. You can see the gas bottles on the right. We use SF6 in gas switches to hold off high voltages until a little pulse of electricity causes the gas inside the switch to ‘breakdown’ and become conducting, closing the switch. When breakdown occurs, small clumps of metal soot fly off the electrodes and into the gas, contaminating it. The orange box in the middle picture is our gas scrubber, which removes the soot. All the plastic piping there transfers the gas around the lab to the right place. The panel in the right image allows us to control the gas pressure in various places – too little pressure in the switch and it will breakdown early, and our experiment won’t work.

Most of our insulating fluid is oil. Air breaks down at relatively low voltages, so we need to surround the capacitors with a better insulator. Oil fills the four capacitor banks, and keeps the electrical charge where we want it to be. When we need to fix one of the banks, all of the oil is pumped upstairs to a holding tank using the pump setup in the main image. There are lots of valves and filters to redirect the flow and keep the oil clean – if it gets contaminated, it won’t be able to prevent electrical breakdown.

Some smaller volumes of oil need topping up occasionally as they leak – we have these little tupperware boxes (inset image) that we fill with oil and let gravity top up any leaky sections for us. Then we just need to refill the tupperware from time to time. A series of safety interlocks prevent us from firing MAGPIE when one of the tupperware boxes is empty.

Oil is great at preventing electrical breakdown on long time scales, like seconds or milliseconds. For fast voltage pulses on the order of nanoseconds we need something better, and we use deionised water. The ions in water come from minerals, and they can conduct electric charge. We deionise the water using chemicals contained in the three barrels in the left image, and the water holds off the voltage in the main pulse forming lines of MAGPIE. Interestingly, deionised water isn’t actually that good an insulator over a long period of time, so we don’t use it in the capacitor banks.

We use clean air to keep dust away from all the optics in our system – there are too many to dust by hand! The big pipes in the left image come from air recirculators, which constantly pump air into our optics cabinets. The bulging plastic sheet shows the high pressure inside the cabinet, which encourages dust to flow out and not re-enter.

So there are a few of the fluids we make use of to allow MAGPIE to work. The lab is quite mature now, and there are excellent systems in place so that we don’t need to spend all day traipsing round with a bucket, topping things up by hand. In some cases, it’s still not clear to me why we use one fluid over another, but sometimes the reason is just because it works.